How Epoxy Shot Molding Boosts Product Quality: A Take A Look At Its Advantages and Uses

Epoxy shot molding stands out for its unique advantages when it comes to boosting item quality. You'll locate that this process not just develops high-strength, lightweight parts however additionally allows for intricate styles and superior surface finishes. Yet what really establishes epoxy injection molding apart in numerous markets? Allow's explore the essential benefits and applications that make it a necessary choice for suppliers today.

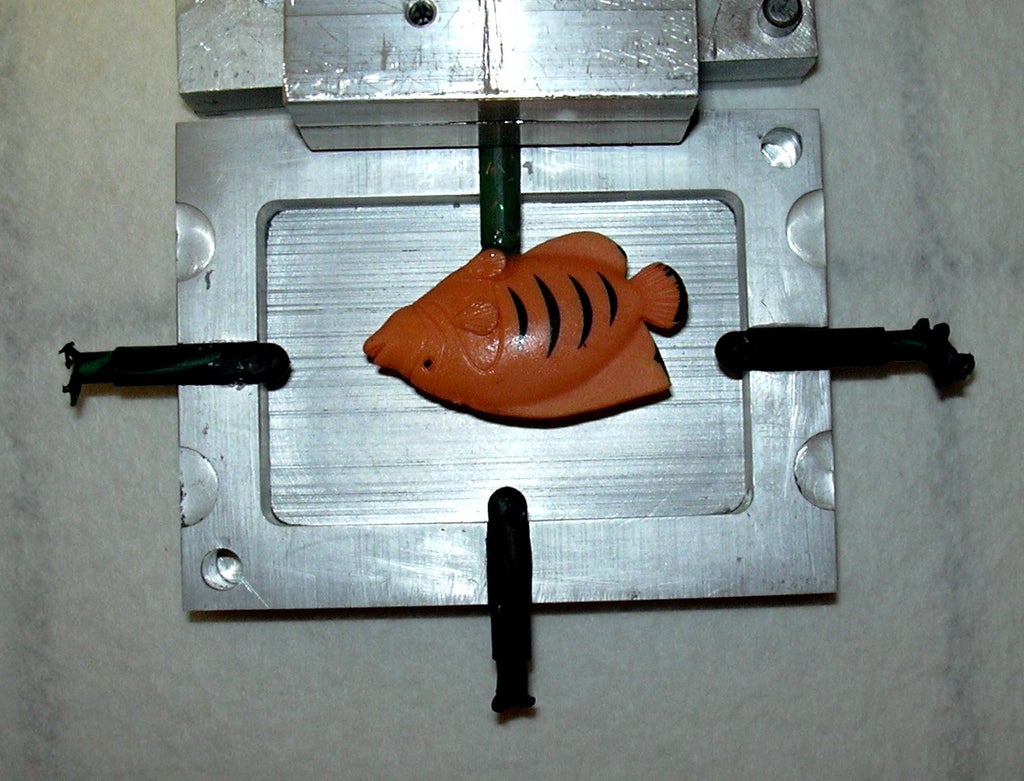

The Essentials of Epoxy Shot Molding

Epoxy injection molding is a remarkable procedure that integrates precision and convenience to produce durable elements. You start by blending epoxy resin with a hardener, which launches a chain reaction, causing a solid product. The blend's viscosity enables it to flow quickly into mold and mildews, capturing complex details and intricate shapes.Once the epoxy is injected right into the mold, it treatments under regulated temperature and stress, making sure a strong bond and outstanding structural stability. You can readjust the solution, permitting boosted homes such as enhanced resistance to chemicals or boosted thermal stability.This process is specifically useful for generating intricate components made use of in different sectors, consisting of automobile, aerospace, and electronic devices. By leveraging epoxy injection molding, you're able to attain premium, lightweight elements that fulfill stringent performance demands. On the whole, recognizing the basics of this molding method establishes the structure for valuing its more comprehensive applications and benefits.

Key Benefits of Epoxy Injection Molding

While discovering the vital benefits of epoxy shot molding, you'll discover that its ability to produce high-strength, lightweight components sticks out. This process enables detailed designs and complicated geometries that conventional molding approaches have a hard time to achieve. With epoxy injection molding, you can anticipate a high level of precision and consistency in every batch, guaranteeing that your products meet limited specifications.Another benefit is the fast treating time, which accelerates production and decreases expenses. You won't have to wait long for your components to establish, enabling faster job timelines. In addition, the adaptability of epoxy formulations indicates you can tailor residential or commercial properties like viscosity and setup time to match your certain needs.Lastly, epoxy shot molding offers excellent surface finishes, which can improve the visual allure of your items and lower the need for second finishing processes. Generally, this approach supplies a trusted option for different applications across numerous sectors.

Improved Longevity and Strength

When you select epoxy shot molding, you gain from enhanced toughness and strength in your elements. This procedure makes use of high-performance epoxy resins that produce robust components capable of enduring harsh problems. You'll discover that these parts withstand wear and tear far better than those made from conventional materials.The solid molecular framework of epoxy supplies exceptional adhesion, ensuring that your item maintains integrity gradually. You can anticipate improved resistance to chemicals, dampness, and temperature changes, which contributes to the long life of your items.Additionally, epoxy shot molding permits exact control over the density and thickness of the parts, even more increasing their stamina. This suggests you obtain light-weight yet extremely resilient components that won't endanger on efficiency. By buying epoxy injection molding, you're ensuring that your items are constructed to last, offering satisfaction and improving general quality

Convenience Throughout Industries

Epoxy shot molding reveals its flexibility in different fields, from the automotive industry to consumer electronics and medical device production. You'll locate it plays an essential duty in producing sturdy components that satisfy certain demands. This flexibility not just boosts item efficiency yet additionally opens innovative opportunities throughout these markets.

Automotive Market Applications

Consumer Electronic Devices Innovations

While the automobile field advantages significantly from epoxy shot molding, the consumer electronic devices industry likewise reaps its incentives with cutting-edge applications. You'll discover that epoxy shot molding enhances the toughness and efficiency of various digital parts, from circuit card to units - epoxy injection molding. Its capability to develop lightweight yet solid parts assists in designing sleeker devices, making them a lot more appealing to customers. Additionally, the precision of this molding method assurances that detailed designs are faithfully duplicated, which is vital for high-tech devices. This adaptability allows producers to trying out new styles without endangering quality. By embracing epoxy shot molding, you'll be empowering click to find out more your items to attract attention in an open market, driving advancement and client complete satisfaction

Medical Gadget Production

When it comes to medical device manufacturing, the advantages of epoxy injection molding are difficult to ignore. You'll locate that this strategy permits for specific control over product homes, making sure that gadgets fulfill rigorous wellness criteria. The resilience and chemical resistance of epoxy make it optimal for products that have to hold up against sanitation processes. Plus, the capability to create elaborate designs boosts capability while maintaining expenses down. With faster production cycles, you can bring ingenious clinical options to market faster. Whether find more information you're creating diagnostic tools or surgical tools, epoxy injection molding uses adaptability that satisfies the special demands of the medical field. Welcoming this technology can significantly enhance your product quality and integrity in healthcare applications.

.jpg?imageView2/2/format/jp2)

Cost-Effectiveness and Efficiency

Given the rising expenses of products and production, epoxy shot molding attracts attention as an economical solution for suppliers. This technique allows you to reduce waste and minimize product expenses, as it efficiently uses epoxy material to develop exact elements. With its capability to produce complex shapes in one pass, your manufacturing time reduces significantly, resulting in faster turnaround times.Moreover, epoxy injection molding improves your production performance. The procedure requires much less energy compared to typical techniques, which helps lower operational expenses. You'll locate that the resilience of the final products likewise implies fewer substitutes and repair work, saving you cash in the future.

Environmental Considerations

As concerns concerning ecological influence grow, epoxy shot molding provides an extra sustainable production option. This process usually generates much less waste than typical techniques, allowing you to optimize product usage. By making use of thermosetting polymers, epoxy injection molding produces strong, resilient products that often call for less constant substitute, which reduces overall consumption and waste.Moreover, epoxy resins can be developed to minimize unpredictable natural compounds (VOCs), decreasing hazardous discharges during production. You'll also find that the power effectiveness of this method can bring about lower carbon footprints compared to various other producing processes.Additionally, several epoxy solutions are recyclable, offering you the opportunity to repurpose products as opposed to sending them to landfills. By selecting epoxy shot molding, you're not just enhancing product high quality; you're also making an accountable option for the atmosphere, aligning your production methods with sustainability objectives.

Future Trends in Epoxy Injection Molding

As you look in advance in epoxy injection molding, you'll discover interesting improvements in material growth that improve performance and sturdiness. Automation is readied to boost performance, making processes faster and more cost-effective. And also, incorporating sustainable practices will help meet growing ecological demands while maintaining quality.

Advanced Materials Advancement

While the standard applications you could try these out of epoxy injection molding have actually currently confirmed reliable, emerging trends in advanced products advancement are readied to transform the industry (epoxy injection molding). You'll see that scientists are now focusing on incorporating nanomaterials and bio-based materials right into epoxy formulas, enhancing buildings like toughness, versatility, and thermal resistance. These advancements not only improve product performance yet additionally lower ecological influence. As you discover these improvements, you'll find that incorporating clever materials can result in self-healing capabilities and flexibility in different conditions. With these developments, you'll have the ability to develop items that meet the needs of contemporary consumers while pushing the limits of what epoxy injection molding can achieve. It's an exciting time to be associated with this transformative area!

Automation and Performance

With the surge of automation in production, epoxy injection molding is readied to become more efficient than ever before. You'll observe that automated systems improve processes, reducing human error and boosting accuracy. This technology permits for faster production cycles, which indicates you can satisfy need without giving up top quality. Robotics and advanced software program are increasingly being integrated into the molding process, enabling real-time monitoring and adjustments. You'll find that these developments not only enhance consistency however additionally enhance material usage, lessening waste. As automation remains to advance, you can expect even higher levels of performance and performance. Embracing these improvements will place you at the forefront of the market, guaranteeing your items stay affordable in a swiftly transforming market.

Lasting Practices Integration

Incorporating sustainable practices into epoxy shot molding is coming to be essential for businesses aiming to reduce their ecological influence. You can begin by sourcing environmentally friendly materials and using recycled material in your items. This not just minimizes waste however also interest eco aware customers. Applying energy-efficient equipment and optimizing manufacturing procedures can further lower your carbon footprint.Additionally, take into consideration embracing a closed-loop system to reuse waste and decrease product use. Consistently reviewing your supply chain for sustainability can likewise assist you make informed choices that straighten with green objectives. By welcoming these methods, you'll not only improve your brand's reputation yet likewise contribute to a healthier earth, setting a positive example in the market for future generations.

Often Asked Inquiries

What Kinds of Products Are Commonly Made With Epoxy Shot Molding?

You'll find epoxy shot molding frequently utilized for automotive components, electronic parts, medical devices, and different commercial applications. Its adaptability enables you to create durable, specific items that meet varied practical requirements successfully.

Just How Does Epoxy Contrast to Other Molding Products?

You'll find it uses superior toughness, sturdiness, and chemical resistance when you contrast epoxy to various other molding materials. It's also less prone to bending, ensuring your products keep their stability under different conditions.

Can Epoxy Shot Molding Be Used for Small-Scale Production?

Yes, you can absolutely utilize epoxy shot molding for small manufacturing. It offers accuracy and versatility, making it perfect for creating elaborate layouts while preserving top quality, which is necessary for specific jobs and prototypes.

What Is the Normal Lead Time for Epoxy Injection Molded Components?

Commonly, you can expect a lead time of 4 to 6 weeks for epoxy injection formed parts. Aspects like style production, tooling, and complexity quantity can influence this timeframe, so plan appropriately.

Exist Details Precaution for Handling Epoxy Materials?

Yes, there specify precaution for dealing with epoxy materials. You must put on handwear covers, safety glasses, and a mask to prevent skin call and inhalation. Always operate in a well-ventilated location to reduce exposure dangers. When it comes to improving item high quality, epoxy injection molding stands out for its distinct benefits. With epoxy injection molding, you can expect a high level of accuracy and consistency in every set, making sure that your products meet limited specifications.Another advantage is the fast treating time, which speeds up production and minimizes prices. Furthermore, the versatility of epoxy formulations suggests you can customize buildings like thickness and setting time to match your details needs.Lastly, epoxy injection molding offers excellent surface coatings, which can boost the visual appeal of your products and lower the need for additional finishing procedures. By making use of thermosetting polymers, epoxy injection molding generates strong, resilient items that usually call for much less regular replacement, which decreases total intake and waste.Moreover, epoxy resins can be developed to minimize unstable natural compounds (VOCs), decreasing unsafe emissions throughout manufacturing. With these advancements, you'll be able to develop products that meet the demands of modern-day consumers while pushing the borders of what epoxy shot molding can achieve.